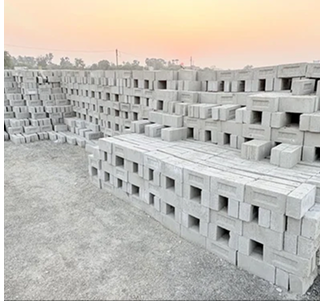

Fly ash brick (FAB)

Fly ash brick (FAB) is a building material, specifically masonry units, containing class C or class F fly ash and water. Compressed at 28 MPa (272 atm) and cured for 24 hours in a 66 째C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw cycles. Owing to the high concentration of calcium oxide in class C fly ash, the brick is described as "self-cementing". The manufacturing method saves energy, reduces mercury pollution, and costs 20% less than traditional clay brick manufacturing.

What Is FLy Ash Bricks-

Fly ash is a byproduct from burning pulverized coal in electric power generating plants. During combustion, mineral impurities in the coal (clay, feldspar, quartz, and shale) fuse in suspension and float out of the combustion chamber with the exhaust gases. As the fused material rises, it cools and solidifies into spherical glassy particles called fly ash. This can be used as a reinforcing agent in the manufacture of bricks,

Specification-

Colour

GREY

Basic Ingredients

Fly Ash + Cement + Sand + Stone Dust + Water

Density (kg / cubic meter)

1,600 - 1,700

Compressive Strength (kg / cm sq.)

80-100*

Water Absorption

15%

Drying Shrinkage

0.03%

Breakage in Transit

Less than 2%

Efflorescence

YES

Mortar saving (during laying)

10-15%

Mortar saving (during plaster)

FOB

The Raw Materials-

Leveraging on our skilled and qualified professionals, we are actively involved in offering a trendy range of Autoclaved Aerated Concrete Block(aac Block) to our valuable customers at pocket-friendly prices.Leveraging on our skilled and qualified professionals, we are actively involved in offering a trendy range of Autoclaved Aerated Concrete Block(aac Block) to our valuable customers at pocket-friendly prices.

Loss on Ignition (LOI);

fly ash loses weight when it burns at about 1000 째C due to presence of carbon and water. The weight loss happens due to carbon combustion and moisture evaporation is called "Loss on Ignition(LOI)". This is expressed as percentage. The lower the loss of Ignition, the better will be fly ash. As per BIS it should not be more than 5%.

Fineness

Fineness; the fine fly ash has more surface area available to react with lime, thus more will be the pozzolanic activity of fly ash. The greater pozzolanic activity contributes to the strength of fly ash brick. As per BIS it should not be more than 320 m2/kg.

Calcium (CaO)

Calcium (CaO) content; the pozzolanic reactivity of fly ash is more in high calcium fly ash. The greater the pozzolanic activity leads to higher the strength of fly ash brick. As per ASTM C618 fly ash is classified into two; Class C contains more than 10% lime and Class F fly ash contains less than 10% lime

BENIFITS

Of FLY ash bricks

Quality

Interlocking Paver Blocks Manufacturer In Udaipur under plant conditions guarantees accessibility

Strong

Interlocking Paver Blocks Manufacturer In Udaipur under plant conditions guarantees accessibility

Handle Weather

Interlocking Paver Blocks Manufacturer In Udaipur under plant conditions guarantees accessibility

Long-Lasting

Interlocking Paver Blocks Manufacturer In Udaipur under plant conditions guarantees accessibility

Ready to Use

Interlocking Paver Blocks Manufacturer In Udaipur under plant conditions guarantees accessibility

Colorful and Durable

Interlocking Paver Blocks Manufacturer In Udaipur under plant conditions guarantees accessibility

Ready to Use

Interlocking Paver Blocks Manufacturer In Udaipur under plant conditions guarantees accessibility

Colorful and Durable

Interlocking Paver Blocks Manufacturer In Udaipur under plant conditions guarantees accessibility

FAQ

Frequently Asked Question

1. What Are Ash Bricks ?

Clay bricks are building materials made from clay that's molded, dried, and fired in a kiln to form durable, rectangular-shaped bricks used in construction.

2. How Are Ash Bricks Made ?

Clay bricks are building materials made from clay that's molded, dried, and fired in a kiln to form durable, rectangular-shaped bricks used in construction.

3. What are the Advantages of Ash Bricks?

Clay bricks are building materials made from clay that's molded, dried, and fired in a kiln to form durable, rectangular-shaped bricks used in construction.

4. How Do Ash Bricks Compare to Other Building Materials?

Clay bricks are building materials made from clay that's molded, dried, and fired in a kiln to form durable, rectangular-shaped bricks used in construction.

5. Can Ash Bricks be Recycled?

Clay bricks are building materials made from clay that's molded, dried, and fired in a kiln to form durable, rectangular-shaped bricks used in construction.

6. Are Ash Bricks Resistant to Moisture?

Clay bricks are building materials made from clay that's molded, dried, and fired in a kiln to form durable, rectangular-shaped bricks used in construction.